- 08 octobre 2021

- En Mari Genova, Satish Beella, Bas van den Berg & Mark Leemhuis

Designing a face mask with a high level of filtration

sustainable MATERIALS AVOID pollution caused by single-use personal protective equipment

The problem of single-use personal protective equipment (PPE) made from non-renewable resources polluting the environment encouraged the creation of a circular face mask. The main factors that influence the design of a face mask that protects the user from COVID-19 were investigated. According to the findings, these are filtration, fit-performance, and comfortability. Therefore, the two following goals were set for this project, to design a face mask (1) produced in the Netherlands using 50% local circular materials and 50% recyclable materials and (2) that perfectly fits men's and women's faces.

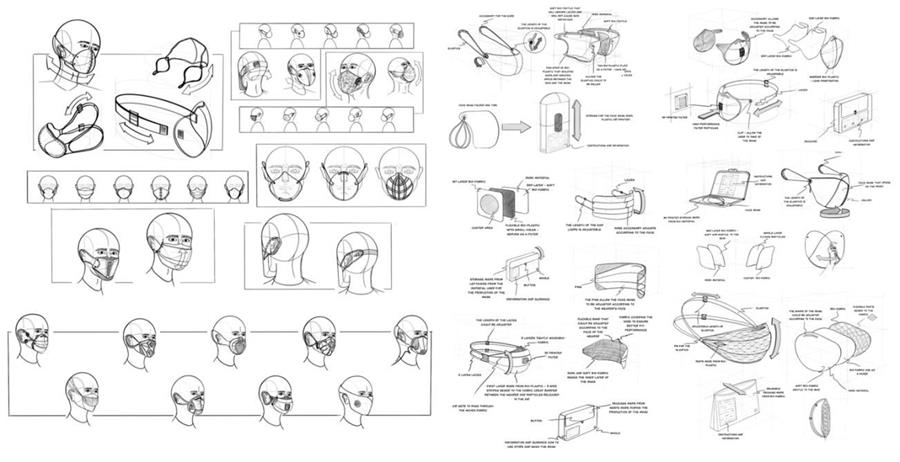

MINI face mask, presented in image 1, meets the final goals as it has a high level of filtration and is made from biobased, biodegradable and recycled materials. Moreover, the product is adjustable, washable and comes with a storage bag made from the waste produced during the manufacturing process, which, in turn, contributes to the overall circularity of the product.

Mission Zero

“The Centre of Expertise ‘Mission Zero’ at The Hague University of Applied Science empowers learners to create a sustainable future and offers a platform where students, researchers and businesses can address environmental issues. To this end, Industrial Design & Engineering student Mari Genova has carried out the research presented in this paper as her graduation thesis topic. Mari was supervised by Bas van den Berg (lecturer Mission Impact and educational director Mission Zero), Satish Beella (lecturer and researcher Industrial Design & Engineering) and Mark Leemhuis (lecturer Process & Food Technology and researcher Technology for Health). Mari is currently active as a junior researcher at ‘Mission Zero’ and will continue her research activities.”

From idea to an environmentally friendly solution

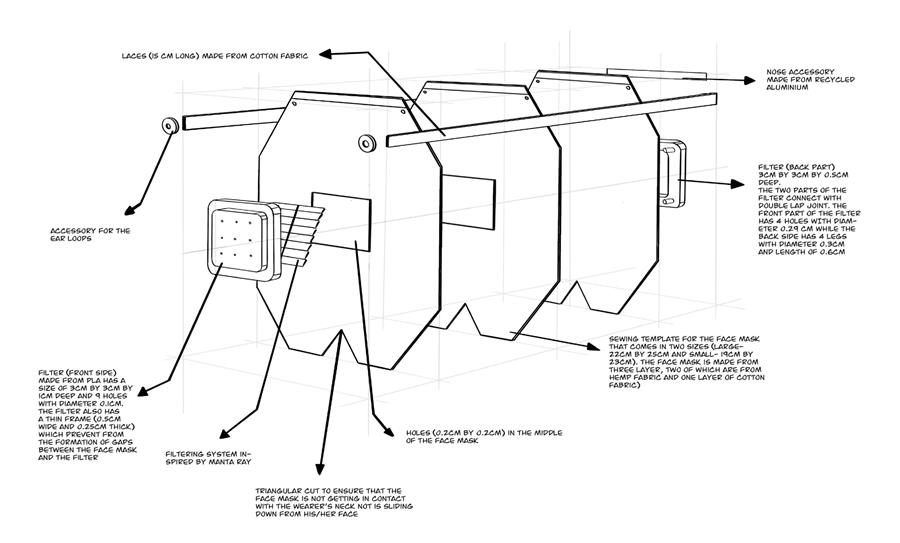

After translating the research findings into requirements, the ideation process, depicted in image 2, began. A concept was chosen by brainstorming the face mask's shapes and attachment methods to ensure fit performance and comfort, filtering systems that will provide the highest possible level of protection, and storage units that will prevent the face mask’s external contamination. The idea represents a face mask made from sustainable materials that has a filter and adjustable headbands.

Although the materials determine the face mask's level of filtration, the fit performance is equally essential

To test the design, sewing templates, sizes, and attachment methods, 16 low- and high-fidelity prototypes were created. Moreover, target group representatives further evaluated the chosen high-fidelity prototype. They all found the face mask comfortable as they did not encounter problems like sliding down or forming gaps. However, all participants had a hard time putting on and taking off the mask because of the headbands going over the head. Based on their feedback, additional improvements were made, which led to the creation of the final product.

Biodegradable Materials

The MINI face mask has three layers of biobased materials. Antibacterial hemp fabric with 600 threads per inch is used for both the first and the second layers. The material is chosen because it is produced in the Netherlands from the fast-growing plant hemp, and it is biodegradable. The first layer is water-resistant as it is 1/3 coated. It acts as a barrier between the person wearing the mask, and respiratory droplets (RD) released in the air without creating side-leakages that decrease the face mask’s performance. When some RDs pass through the first layer, their kinetic energy is reduced, so the particles have much lower momentum, which hinders their passing through the second layer [1]. However, hemp fabric is rough to the touch, so for the inner layer of the mask, 100% cotton fabric was chosen. Cotton is a hydrophilic material that further enhances filtration by absorbing the RDs released by the user.

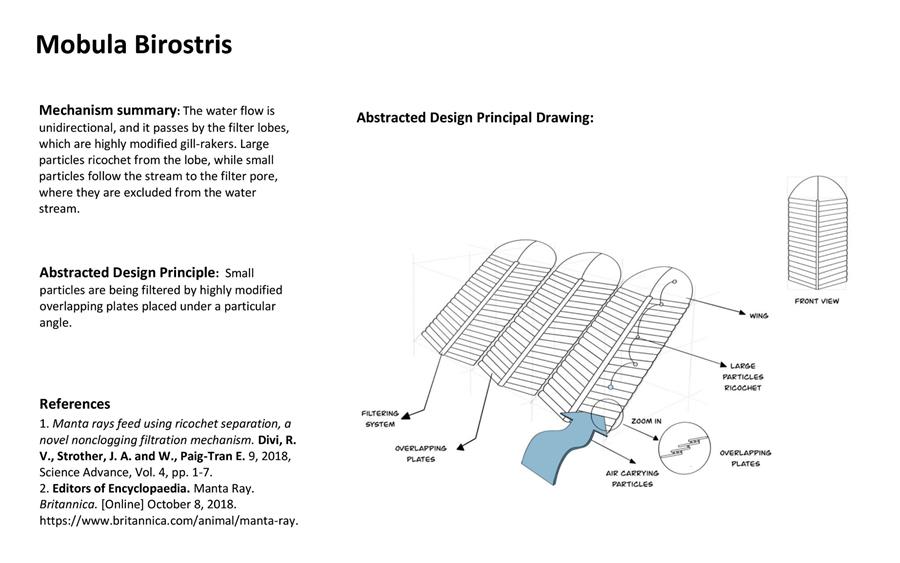

Although the materials determine the face mask's level of filtration, the fit performance is equally essential. Therefore, after studying Dutch people's facial characteristics and the Dutch marker, an adjustable face mask that comes in two sizes was made (small size "S" is 14cm long and 20cm wide, large "L" size 16cm by 22cm). The design allows the face mask to unfold according to the user's face, and three distinct sections could be recognized: the nose, middle, and chin. Specific details were added to each section to achieve an optimal result (see image 3). For example, a supplementary hem was made at the top of the nose section, which allows the adjustable nose accessory made from recycled aluminium, which prevents the formation of gaps, to be easily removed when the mask is disposed of.

The ear loops have been designed to eliminate one of the user's main complaints, the pain behind the ears. That has been achieved by creating adjustable ear loops, which are sewed to the lower corner of the middle section while their other end goes through a hole at the top corners of the same area.

As seen in image 1, an accessory was included in the top section of the two ear loops. That accessory allows the user to fixate the ear loops after putting the mask on. Also, the chin section has a 'V' cut, which prevents the face mask from sliding down.

Biomimicry enables a nature-friendly filter

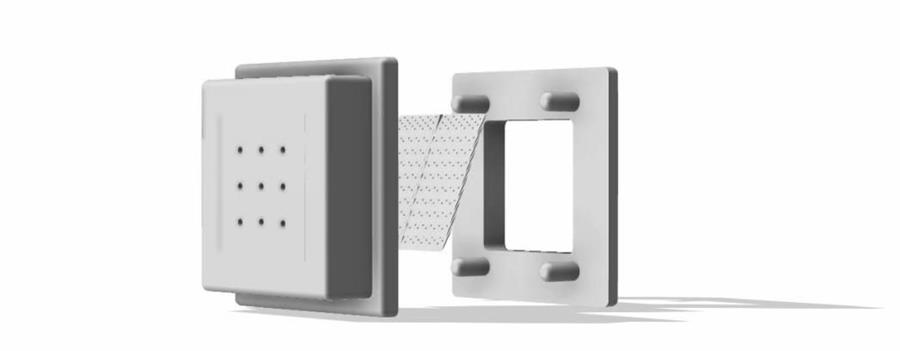

Biomimicry practices were used to avoid compromising on filtering capacity and ensure the highest possible level of protection while being environmentally conscious. According to Stevens et al. (2020), Biomimicry is a learning field based on 3.8 billion years of nature’s strategies that teach us to find innovative design solutions by mimicking forms, processes, and systems [2]. By applying the Biomimicry Design Thinking Framework and following the Life’s principles, a long-lasting filter made from biodegradable materials was designed. The process started by selecting the function (filter small particles), then a library of organisms that use this function was created. Next, the mechanisms of how these organisms filter particles were studied. Later, the mechanisms were translated into an Abstracted Design Principle (ADP – translating the biological principle into a design language). The ADP's inspired the ideation phase, and after few iterations, an idea based on Manta Ray's filtering system (see image 4) was chosen. The concept is designed following Manta Ray’s ADP (see image 5).

Image 4: Manta Ray's Mechanism

Image 5: Abstracted Design Principle

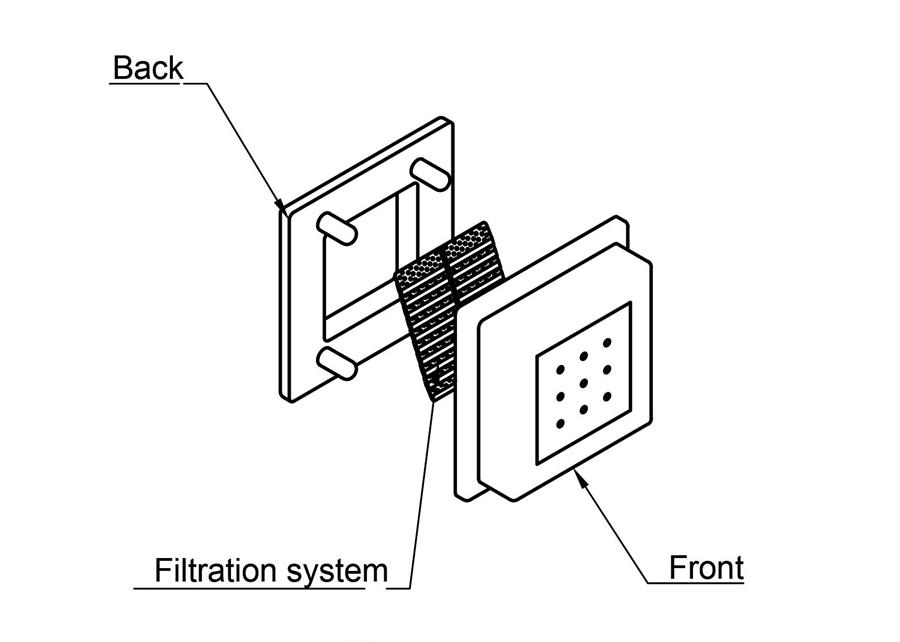

The filter’s body, positioned at the middle of the mask, is made from PLA (Polylactic acid) and has a square shape of 3 cm by 3 cm and a frame of 0,5 cm wide (see image 6). Its fast disassembly is ensured by a double lap joint that connects the filter's front and backside.On the filter's front side, nine holes with a size of 1 mm in diameter block big RD from entering the inside of the filter, where the filtering system is positioned. It represents a tube fitted in the filter’s body at 45 degrees that holds nine overlaid plates (9.5 mm long) with small bumps (see image 6). When the air enters the filter, it moves parallel to the plates. Following the cross-flow filtration method instigated by the 45-degree angle tilt of the filter, the large particles carried inside ricochet from the plates while the smaller ones get stuck between the plates and filtered air passes through. Finally, the inner third layer of the face mask is pinched between the filtering system and the backside of the filter's body, hence creating the last barrier for the particles.

pandemic requires more innovative solutions

MINI was designed to lower the waste produced from face masks and protect people from COVID-19 through its innovative filtration system. However, to explore the full potential of this face mask, further research on the filtration system is required. For example, the face mask and the filtration system filter should be tested against small particles in a laboratory setting. Such laboratory tests will also examine if the filter’s efficiency has changed after scaling down the model inspired by the Manta Ray. Also, topics such as renewable production and the end-life of the product should be further explored.

In conclusion, the COVID-19 pandemic started as a health crisis but slowly evolved into an environmental one. By offering an innovative solution that does not compromise the level of protection and lowers the level of environmental pollution, that project can provide a solution to the problems developed due to the pandemic.

References

1. Performance of fabrics for home-made masks against the spread of COVID-19 through droplets: A quantitative mechanistic study. Aydin, Onur, et al. 2020, Extreme Mechanics Letters.

2. Biomimicry design thinking. Stevens, L., et al. 2020.

3. Editors of Encyclopaedia. Manta Ray. Britannica. [Online] October 8, 2018. https://www.britannica.com/animal/manta-ray.

4. Manta rays feed using ricochet separation, a novel nonclogging filtration mechanism. Divi, R. V., Strother, J. A. and W., Paig-Tran E. 9, s.l. : Science Advance, 2018, Vol. 4, pp. 1-7.