Salt in wastewater: from cost factor to cash point

SALTTECH's pioneering DyVaR® technology applied in the German dairy industry

With the help of the DyVaR® concentration and crystallization technology from SALTTECH, it is possible, effectively and highly efficiently, to not only dispose of the milk salts that arise in the course of the manufacturing process, but also to increase or decrease the salt concentration in accordance with the Recycling Management Act (KrWG). Liquid side streams from milk processing are effectively converted into new products and thereby supporting the circular economy. The DyVaR technology from the Dutch technology company SALTTECH has now successfully put a reference system into operation in the German dairy industry for the first time after several years of preparation.

Initial situation and background

The patented so-called Dynamic Vapor Recovery (DyVaR®) technology from SALTTECH with its unique, modular, robust and very efficient evaporation cyclones helps LACTOPROT at the production site in Leezen, Germany, to turn highly concentrated brine flows into a valuable fertilizer product and fresh water. With worldwide customers of high-quality products, LACTOPROT Germany GmbH from Kaltenkirchen can be classified as one of the international market leaders in caseinate production. In close cooperation with the customer's R&D team, SALTTECH carried out effective bench tests and continuous pilot tests, which led to a robust, turnkey solution for upgrading the acidic milk permeate that occurs during caseinate production, which is initially concentrated by means of reverse osmosis (RO) and because of the high concentration of milk salts and organic components, it had to be disposed of as a waste stream. Modern dairies such as LACTOPROT in Leezen produce caseinates for a multitude of applications with the help of the most modern, innovative production technologies, which leads to the use of almost every single component of the milk or whey that is introduced as raw material. One of the few waste streams is the reverse osmosis system concentrate, which collects the milk salts from part of the production process. This special RO concentrate contains elements such as phosphate (P), potassium (K), chloride (Cl), magnesium (Mg), calcium (Ca), other salts and organic substances (COD).

The Business Case

The ambitious project goal was to implement a reliable and cost-effective solution for the further processing of the brine from the RO plant and to concentrate these milk salts more than 10 times with the aim of converting this "waste stream" into fresh water and a valuable alternative fertilizer product for agriculture to convert.

Two trends and environmental developments contributed to the ambitious project goal:

- Until recently, it was allowed in Europe to discharge salt flows into municipal sewer systems or receiving waters without strict restrictions. Due to increasing dry periods and rising salinity, new European environmental regulations came into force to limit a further increase in the direct and indirect discharge of this problematic waste water. This meant that LACTOPROT (and others) had to hand over the RO brines produced to specialized disposal companies for years, which led to high annual costs.

- As a result of the future phosphate shortage, some European authorities such as the Federal Environment Ministry emphasize and support the recovery and reuse of phosphates as fertilizer for agricultural applications.

The aim of the project was to reduce the cost of disposing of the RO concentrate by at least 85% while using the end product (a concentrated mixture of potassium chloride and phosphoric acid as produced by DyVaR) as an alternative fertilizer for agricultural applications to use.

The Challenge

It is well known in the dairy industry that membrane and electrodialysis salts containing milk salts with matrix behavior as described below cannot readily be reliably concentrated using standard evaporation technologies. The reasons for this include:

- High concentrations of chloride;

- Different mixture and different concentration of elements like P, S, Mg, K, Ca;

- Relatively high and fluctuating COD concentration;

- Low pH between 1 and 4.

These properties are technically demanding in conventional treatment processes such as standard evaporation systems. Energy consumption of up to or more than 100 kWh/m3 (condensate) for regular treatment is also not economically attractive. In the dairy industry it is well known that conventional evaporation systems have problems with buildup during the concentration process and that the downtimes of such units can easily reach 50-60% of the total operating time due to the resulting intensive regular acid cleaning. The high chlorine concentration in a classic evaporation system in combination with the extremely low pH value and challenges the service life of all stainless steel components in these conventional systems considerably.

In addition to these process engineering challenges that LACTOPROT was confronted with, the solution also had to meet the following operational requirements, which are specifically relevant for LACTOPROT:

- The DyVaR-60 unit must be easy to use by the operators in all shifts;

- Downtime for cleaning and maintenance should be less than 10%;

- The DyVaR-60 unit should not consume more than 55 kWh/m3 (condensate) for the whole concentration process;

- Continuous addition of steam during operation is not desirable;

- Internet connection for possible direct support and services from SALTTECH;

- Due to the proximity of a residential area, the required maximum noise emission level is <45 dBA.

The Solution

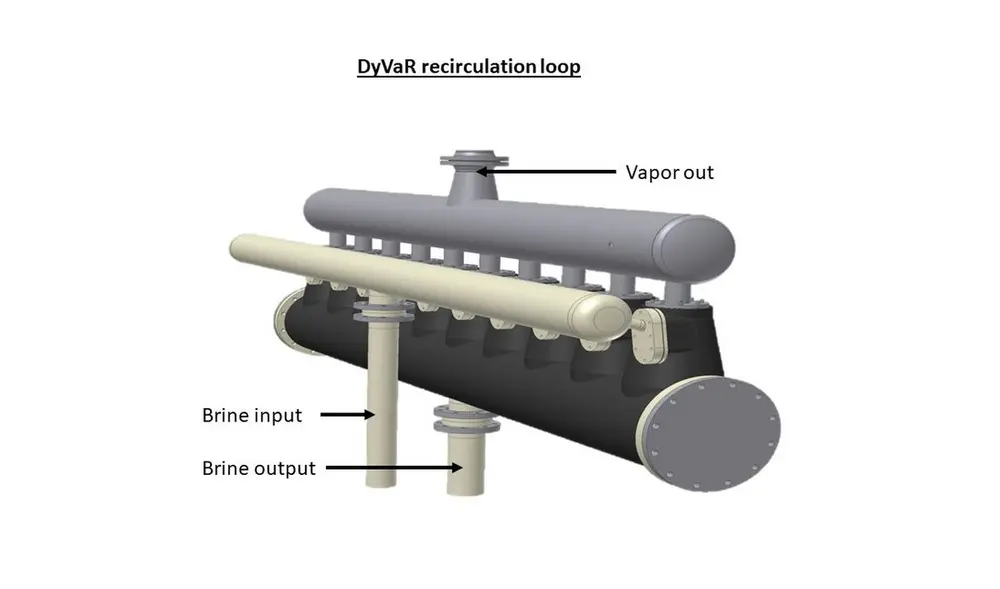

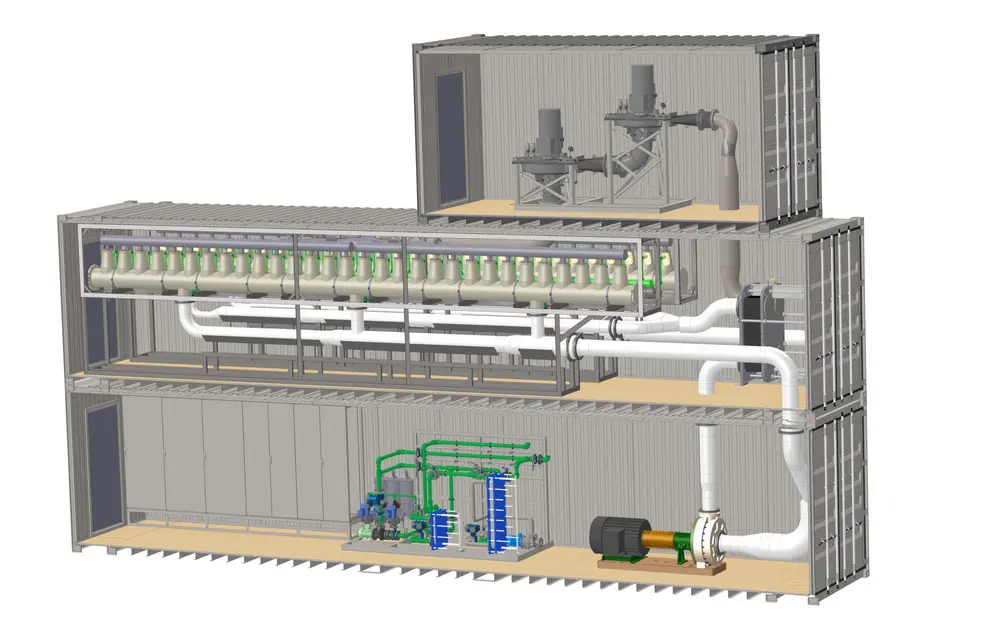

The demanding combination of product matrix and operational requirements required an innovative and highly efficient concentration and crystallization technology called DyVaR. DyVaR is a modular system consisting of cyclones called "Dynamic Vapor Recovery Units" or "DyVaR Units". The device consists of non-metallic components with a highly modular structure. Thanks to the unique and patented 3D vapor recovery process, the design of the DyVaR concept is extremely energy efficient.

In order to concentrate and crystallize the incoming brine, it is pumped into the circulation circuit, where it passes the DyVaR units several times at high speed to separate the water from the salts and organic matter. The process is designed in such a way that precipitation in the DyVaR units is only stimulated where salt crystals form.

The direct benefits of DyVaR

- Treatment of severely impaired water bodies of any concentration with minimal pre-treatment;

- The solution for the Zero Liquid Discharge (ZLD) requirement treats demanding bodies of water for the production of fresh water or reusable process water and highly concentrated salts or solid salt;

- A technology almost insensitive to scaling and fouling;

- Designed for low-cost modular field applications with minimal site work based on standard stackable containers;

- Non-metallic wetted components in the brine circulation loop;

- “One system fits all designs” so that it can be implemented either as a concentrator or as a solids producer.

About Salttech

Salttech is a technology company, founded in 2011, and is active in the Water treatment industry, focusing on treatment of high concentrated brine streams. Salttech is part of the Dutch Water Technology group (DWT). Among Salttech, Biotrack and Aqana are part of DWT. Aqana is specialized in anaerobic wastewater treatment and has proved its worldwide success with the DACS technology. Biotrack is a company specialized in the detection of bacteria and viruses in liquids and blood. During the current pandemic, their highly accurate Aquascope was used for detection of Covid-19. The Salttech team consist of chemical, electrical and process engineers and has a seasoned management team. Due to the growing ZLD business and increasing focus on water recovery worldwide, the (international) team is rapidly growing.