Defossilizing industry: the complex path toward a sustainable future

Alternative carbon sources and ex-ante assessment in industrial transformation

It is an exciting, challenging, and daunting time. We are poised to carry out the biggest change in the power and industrial sectors since the Industrial Revolution. Achieving a net-zero sustainable economy, as the EU intends by 2050, requires a deep transformation of our economy. In the power sector, the substitution of fossil fuels as an energy source has already gained momentum. In the industrial sector, however, replacing fossil fuels as raw materials for producing chemicals and fuels has lagged behind.

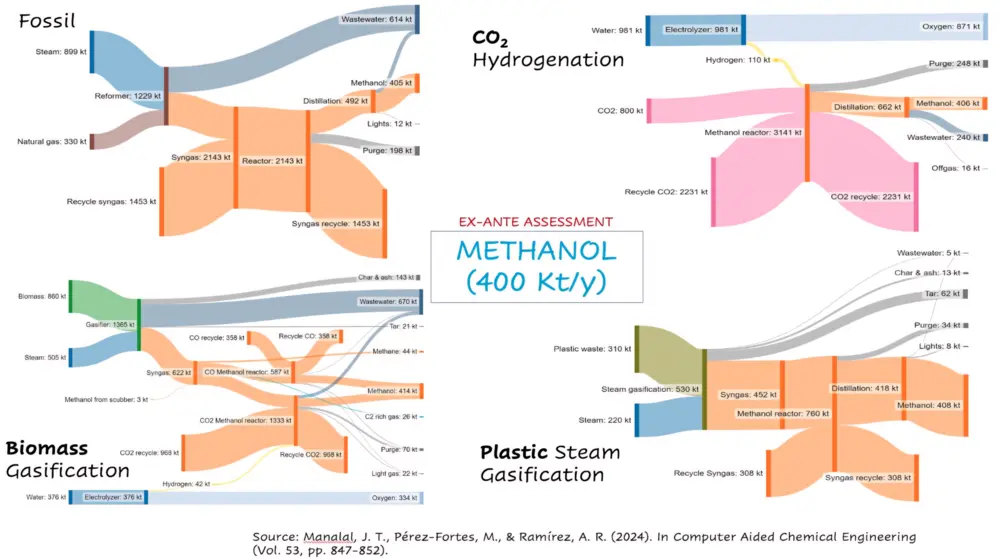

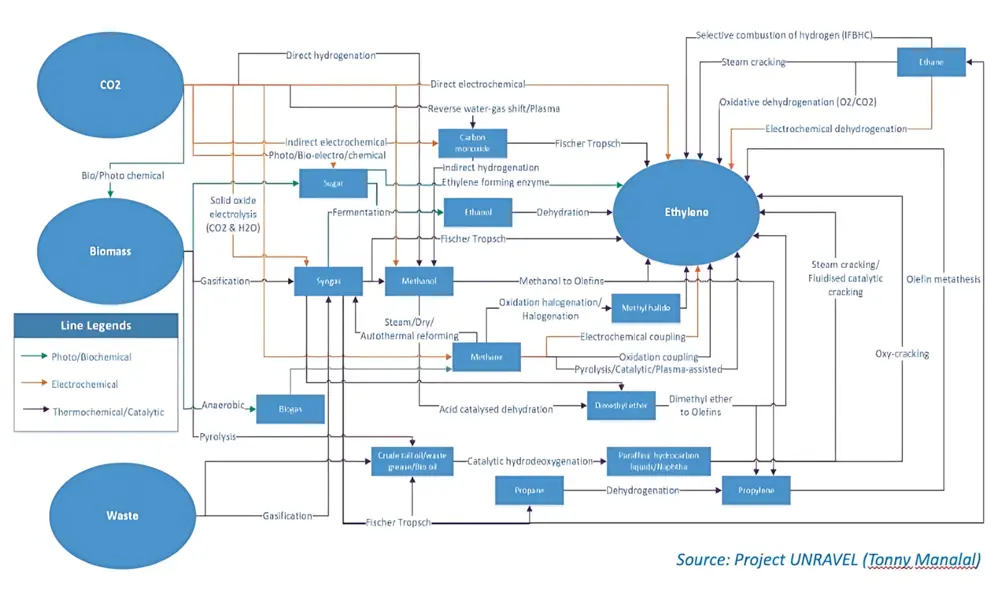

Today, 90% of products in the chemical industry are made from fossil fuels, and the demand for materials and chemicals is projected to double by 2050. Replacing oil, natural gas and coal with alternative carbon sources (ACS) such as CO2, biomass, or plastic waste provides major opportunities and challenges for technology developers, industries and policymakers not only because major shifts in core processes will require breakthrough technologies that are not yet commercially available, but also due to increasing concerns regarding the availability of sustainable carbon sources.

"Industrial symbiosis is a key strategy to optimize consumption of energy and materials, minimize waste and maximize material reutilization"

Ex-ante technology assessment (ETA)

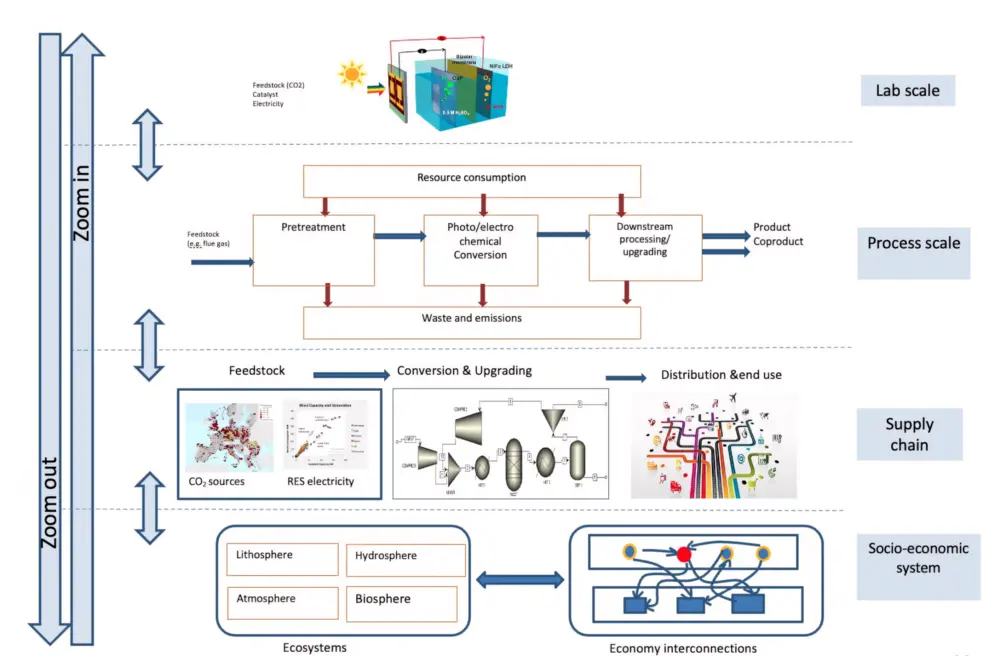

Ex-ante technology assessment (ETA), a combination of techno-economic, environmental, and risk analysis, can provide knowledge suitable for actively shaping technology development and deployment. Conducting these types of assessments is important because processes that use ACS are not inherently more efficient or environmentally sound than their petrochemical counterparts. This is due to a combination of factors, including the low level of maturity of most ACS-based technologies, and the recalcitrant nature of the feedstock towards chemical and biological degradation, e.g., lignin or in the case of CO2, a low energetic level and high thermodynamical stability, which requires high energy input and catalysts for its transformation.

ETAs have been primarily conducted as one-to-one comparisons between specific ACS-based processes and their fossil-based counterparts, such as fossil-based vs. bio-based fuels. In this type of assessment, a value chain approach is often used to consider the flow of processes, from input suppliers to end-market buyers. While these assessments provide valuable insights, they have an important pitfall. They simplify (or neglect) the reality of today’s industrial clusters where ACS processes will ultimately be deployed.

Industrial clusters: complex interdependencies

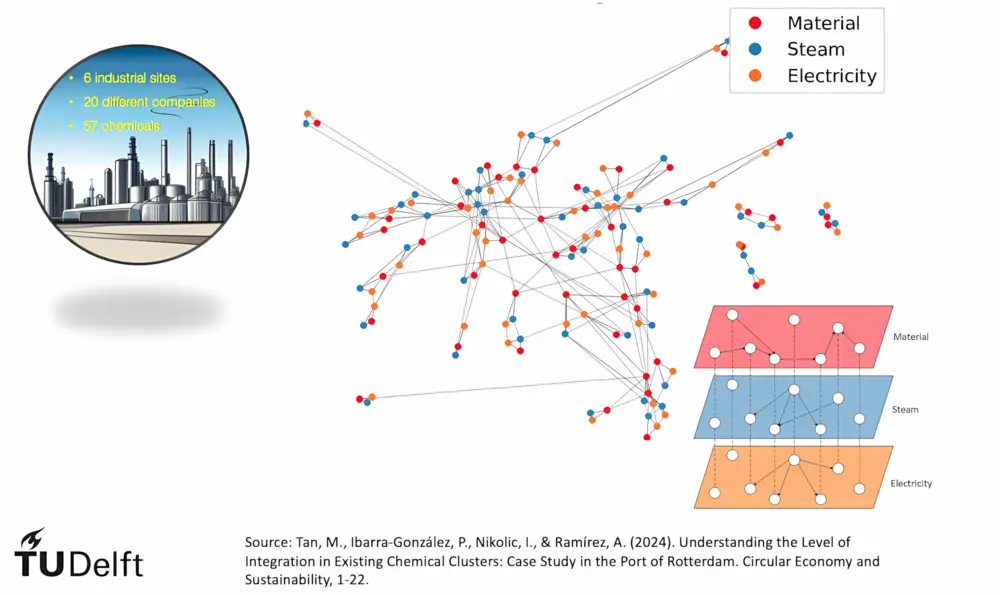

Most industrial clusters have evolved over many decades and during this time, symbiotic connections have been developed between industrial firms and processes in response to various pressures, such as raw material and energy prices or environmental regulations. This has resulted in complex industrial systems with intertwined processes between and within industries. In the coming years, the number and significance of such interconnections is expected to increase as industrial symbiosis is a key strategy to optimize consumption of energy and materials, minimize waste and maximize material reutilization (circular economy).

"The grand challenge is the transformation of multiple and interlinked processes and value chains"

Strong interdependences can, however, hinder defossilization efforts, as changes in any single process will inevitably affect other processes (possibly operated by other firms), both at the local scale of an industrial cluster and in the supply chains involved. Attempting to defossilize industrial systems without considering the local reality of highly interconnected industrial processes, could unintentionally result in systems that are more complex, less resource efficient and produce (net) more emissions. The grand challenge is, therefore, not the defossilization of individual processes or products but the transformation of multiple and interlinked processes and value chains.

Developing Advanced Models for Systemic Analysis

At TU Delft, we are tackling this challenge by developing ETA methods and tools to evaluate the potential impact of deploying ACS in petrochemical clusters. We develop models of industrial clusters that allow us to comprehensively and systematically analyse the impacts of pathways for defossilizing symbiotic industrial clusters. By using a combination of process-based models that mimic current processes, network analysis that reflects the current level of interconnections between processes, techno-economic and life cycle assessments of fossil and prospective technologies, we are developing new approaches that allow us to take into account relevant conditions. Pathways that appear optimal in the model are also evaluated to assess whether they would increase resource use or emissions outside the cluster boundaries.

Insights from the UNRAVEL project

In the UNRAVEL project (2019-2025), for instance, we developed a model that contains 6 industrial sites, 20 companies, and 57 chemical processes, and used it to evaluate potential defossilization pathways and identify cascading impacts.

The model mimics existing processes, capacities and interconnections in the Port of Rotterdam. We developed a superstructure that allows multi-objective optimization to be conducted. We identified ACS-based technologies, such as gasification and pyrolysis, that trigger the largest changes at higher system levels, and technologies that appear to play a recurring role regardless of the scenario, such as methanol to olefins. The lack of a silver bullet technology is a recurrent insight, as well as the role that land and feedstock availability play as key constraints for the system.

We are currently examining the potential impact of directly defossilizing end-of-value chemicals (instead of chemical building blocks), and in two projects that will start in the coming months, we will be investigating the significance of increasing process flexibility in the defossilization pathways. This work illustrates how Process System Engineering can play a key role not only in guiding technology development, but also in strengthening longer-term and systemic views for industrial transformation.

Who is Andrea Ramírez Ramírez?

Prof.dr. Andrea Ramírez Ramírez is a leading expert in low-carbon systems and technologies. She is a full professor and head of the Department of Chemical Engineering at TU Delft. With a background in Chemical Engineering (Colombia), a master’s in Human Ecology (Belgium), and a Ph.D. in industrial energy efficiency (Netherlands), she previously held academic positions at Utrecht University, focusing on carbon capture and biorefineries. Her research supports industrial decarbonization through ex-ante technology assessment, life cycle analysis, and system modeling. She has received prestigious awards, including the Delft Technology Fellowship and a €1.5 million VICI grant from NWO, and is a fellow of the Netherlands Engineering Academy. Her work continues to shape the future of sustainable energy and industrial transformation.