FOUR ELEMENTARY DOMAINS IN PROCESS INTENSIFICATION

Batch-to-continuous with millireactor technology

PROCESS INTENSIFICATION IN SPATIAL DOMAIN

Ehrfeld Mikrotechnik BTS (Leverkusen, DE) designed, manufactured and supplied a MIPROWA production reactor for Shaoxing Eastlake Biochemical (China) for a production capacity of up to 10,000 t/a. The MIPROWA millireactor with a throughput of about 1m³/h has a nominal width of 400 mm and a length of 7 m and contains about 150 rectangular reaction channels with exchangeable static mixers. Shaoxing Eastlake Biochemical successfully launched the production plant in Shaoxing mid-September 2016. The continuously operated millireactor replaces more than 20 batch reactors.

The fast and strong exothermic reaction is of alkoxylation type. Decision for Miprowa technology was driven by achievable product quality, significantly improved yield, safety aspects and a short return on investment. Scale up started from lab scale by a transition of channel geometries from micrometer to millimeter scale. Compared to established process technologies, a much faster scale-up process could be realized.

Plasma oxidation disinfects water without the addition of chemicals

PROCESS INTENSIFICATION IN THERMODYNAMIC DOMAIN

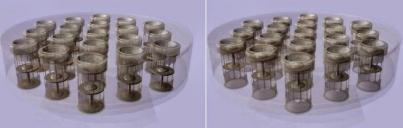

A new technology that uses plasma to kill bacteria and simultaneously oxidize organic material in water systems offers a non-chemical alternative to water treatment in several industry sectors, such as food and beverage, power generation, oil and gas and others. Symbios Technologies Inc. (Fort Collins, Colo.; www.symbiosplasma.com) has demonstrated its TPR4000™ Tubular Plasma Reactor, which generates plasma using low-voltage, direct-current electricity applied across an array of plasma nozzles mounted on a rapidly (1,000 rpm) rotating cylindrical core. The plasma nozzles are equipped with porous frits that allow air to be introduced into the contaminated water, which flows into the reactor from the top and is mixed vigorously by the rotation. The air-supported plasma generates a variety of high-energy electrons and hydroxyl radical species that kill microbes and oxidize organic material in the water. The results demonstrated plasma inhibition of bacteria, with an approximate 6 log decrease in viability with less of one minute aqueous plasma treatment. This new design is scalable (in length of the tube and diameter) in continuous water flow mode and can be expanded with parallel reactors to treat larger volumes of water.

Fractionating multiple ternary feed mixtures in a single plant

PROCESS INTENSIFICATION IN FUNCTIONAL DOMAIN

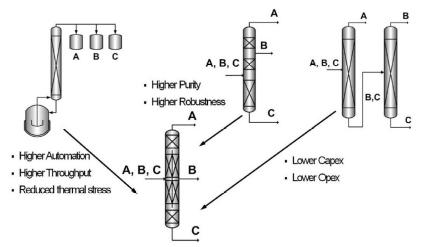

Divided wall column (DWC) has been widely applied for several years, mainly at BASF SE. Now there are about 100 columns are operated worldwide. Lonza Goup AG reported recently about a multipurpose DWC which can replace either batch distillation column or a side draw column or a conventional two-column sequence. In order to fit the DWC to a multi-purpose production facility several new adaptions and enhancements have to be applied. For a flexible liquid split over the two sides of the dividing wall a manually adjustable liquid divider is installed in the column. In order to suit the DWC for any future application the position of the feed and the side stream can be varied over the column height. Moreover it is possible to run the DWC as a common distillation column by splitting the feed in two equal parts and sending it on both sides of the dividing wall. It results in saving of 30% of investment costs. By replacing the batch distillation column with the DWC an increase of 50% throughput as well as 5% yield increase together with increase of purity from 98% to 99.5% could be achieved. At the same time component decomposition is eliminated. The main achievement by substituting two distillation columns with a DWC is a higher product quality in terms of purity and color. The side-draw distillation column was successfully replaced in order to increase the product purity with a DWC which is directly connected to the reactor outlet.

Cyclic distillation

PROCESS INTENSIFICATION IN TEMPORAL DOMAIN

Conventional distillation processes are extremely energy inefficient and require optimization in terms of lower energy use, reduction of capital costs and eco-efficiency. They can be intensified using cyclic distillation. The main idea of cyclic distillation is to separate phase movement of vapor and liquid phase. The process is based on the sequential supply of vapor and water in the column. During vapor period the lack of liquid overflow is achieved by perforated trays. During liquid period the lack of liquid mixing in adjacent trays is achieved with the help of sluice chambers located under the tray.

The liquid supply of the column is divided into two stages. In the first stage liquid is located on the tray without a transfer to the tray below. Vapor runs through the liquid which is assumed as perfectly mixed without a gradient of temperature or concentration. Furthermore all the liquid on the tray has the same residence time and a speed of movement which equals zero. In the second stage the liquid overflows and reaches the tray below.

Maleta Cyclic Distillation LLC reports smaller equipment dimensions with higher equipment productivity, higher separation performance, reduced energy costs by about 25% induced by lower vapor flow rates and two or more times higher throughput compared to conventional processes. Cyclic distillation is applied in ethanol dehydration, atmospheric and vacuum distillation. Also BASF SE reported potential industrial applications.

By Jan Harmsen (Harmsen Consultancy BV)