Rethinking energy use in distillation processes

Towards a more sustainable chemical industry by intensified distillation

The chemical industry uses about one third of the total energy used in industry. When zooming in on the chemical industry, distillation alone is responsible for about 40% of the energy. This article focuses on distillation and potential improvements for a more sustainable future. There is an increasing need and scope for advanced distillation technologies, but they must be considered in the context of the process as a whole. Several challenges and opportunities for research directions towards rethinking the energy use in distillation processes are highlighted.

Energy use in chemical industry

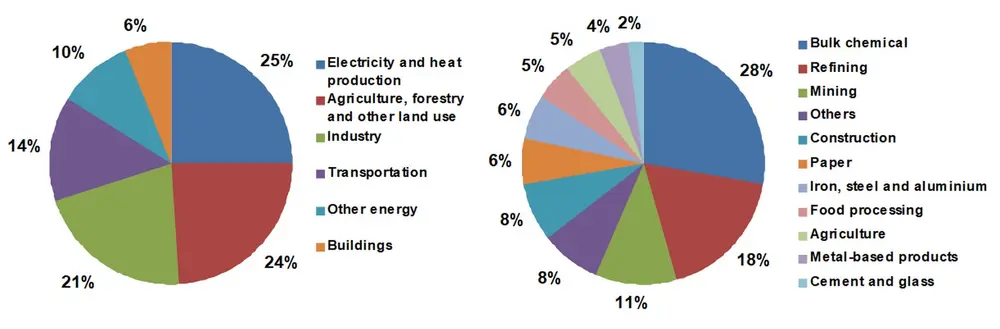

Figure 1 shows a breakdown of industrial energy use (with the bulk chemicals sector being the largest energy user, followed by refining), and the global greenhouse gas (GHG) emissions by economic sector. These figures are broadly representative of other countries worldwide.

Table 1 lists the key figures in the chemical industry in the top European Union (EU). In EU28 the chemical sector consists of 30,000 companies employing 1,171,000 workers, with a capital spending of €22.8 bn, R&D investment of €10 bn, and a turnover of €565 bn.

The EU chemical industry has made a commendable effort to improve energy efficiency, but there is still room for improvement by tackling increased heat recovery (by process integration), low-grade waste heat upgrading (with heat pumps), and especially distillation processes, which are responsible for over 40% of the energy used in the chemical industry. [1]

Tackling the energy efficiency of distillation therefore will have the single greatest impact.

The problem with distillation

Distillation is among the oldest operations in the chemical industry and is still the separations workhorse, because it is simple and effective, but it also has important drawbacks such as high capital (equipment) costs and large operating costs (due to its low energy efficiency). In fact, distillation works as a heat engine with poor efficiency. It imports a considerable amount of heat, which is also (for the most part) rejected, but at a lower temperature. In broad terms, distillation does not consume heat, but degrades it. It is the inability to make effective use of the rejection heat that leads to high consumption. Higher efficiency and thus lower costs are therefore crucial targets for all players in the chemical industry. However, there are no unique answers regarding energy efficiency, as the required minimum energy and the potential saving depend on operating pressures and temperature span, while the utilities available on a chemical site also have an impact on selecting the most suitable technology and its operation.

Distillation can handle a wide range of throughputs, can separate mixtures with a wide range of feed concentrations and can produce high-purity products. These advantages will keep distillation to be the key separation in the process industries for the foreseeable future. Therefore, we must rethink the energy use in distillation and the chemical industry. Here are a few pathways to consider. [1,2]

Advanced distillation processes

Heat pump (HP) assisted distillation

Heat pumping upgrades the level of energy discharged and re-uses it to reduce the consumption of valuable utilities. Besides classic heat pumps, hybrid and novel concepts are being developed to allow higher temperature lifts and coefficient of performance. When waste heat is also available for upgrade, the use of heat pumps is highly advantageous. Various forms of heat pumps can be successfully used in conjunction with distillation (as described in earlier articles): compression HP, absorption HP, compression resorption HP, thermo-acoustic HP, heat transformers, absorption refrigeration (AR).

In practice, the decision to use heat pumps for distillation must follow a careful investigation of all the heat integration opportunities in the context of the overall system. Installing a heat pump in an existing installation can run into space limitations.

Cyclic distillation

This uses a periodic mode of operation. One operating cycle consists of two parts: a vapor flow period (during which the thrust of the rising vapor prevents liquid downflow), followed by a liquid flow period (during which the liquid flows down the column, dropping by gravity to a sluice chamber below the tray and then on to the tray below). No downcomers are needed in operation; thus the plates are inexpensive and the design can be flexible. Improved separation performance is possible as a result of separate phase movement and lack of mixing between the liquid from different trays. Additional key benefits include reduced energy requirements, lower capital costs, and increased column throughput. The challenges related to design and control have been tackled in the recent years, and equipment is readily available for many industrial applications.

Reactive distillation

RD is a PI technique that combines reaction and distillation into a single unit, taking advantage of synergistic effects. RD allows key benefits such as: getting around equilibrium limitations, simplifying complex processes, reducing investment and operating costs (usually by 40-60%), significantly less waste and fewer by-products, improving product quality, reducing thermal degradation, enhancing reaction rate and conversion, achieving high selectivity, performing difficult separations, and accomplishing in-situ energy integration. RD is considered the front-runner of industrial PI with many industrial applications at large scale. To keep perspective, RD is a special case applicable mostly when the reaction uses a heterogeneous catalyst and can be coupled with distillation in the same operating range, which is not always the case. Some processes have no reaction integration options (e.g. crude oil distillation) while other processes require the reaction to be at high temperature and/or with a high heat flux. Also, high heats of reaction prevent integration of reaction and separation into a single operation. Moreover, RD does not lend itself easily to retrofit in an existing installation.

Dividing-wall columns

A DWC integrates two distillation columns of a Petlyuk configuration (consisting of a pre-fractionator that is thermally coupled to a main distillation column) into a single shell. It is applicable to many processes and it has many advantages such as: improved thermodynamic efficiency, with high purity for the middle product stream, compact configuration (2 columns in 1 shell), around 25-30% energy savings (due to no remixing effect), 20-30% lower capital investment (due to using only 1 reboiler and 1 condenser). DWC technology can also be effectively combined with reactive distillation or with heat pumping for enhanced energy savings of up to 60%. The main drawback is that DWCs allow only one operating pressure for the whole separation, leading to a higher pressure drop and temperature span along the column. Although less energy is required, this energy is added overall and rejected at more extreme temperatures than a conventional arrangement.

Optimization of distillation processes

The typical design problem is to find the configuration with the minimum OPEX that produces on-spec products from a given feed mixture of components. This task is not trivial due to the large number of possible alternatives, which grows exponentially with the number of components to be separated. To address the most efficient distillation system requires all of the degrees of freedom (DoF) to be manipulated simultaneously. That means optimizing the distillation sequence (including the use of complex distillation arrangements), heat integration (including pressure optimization of the distillation), and use of heat pumping in the context of the other DoF.

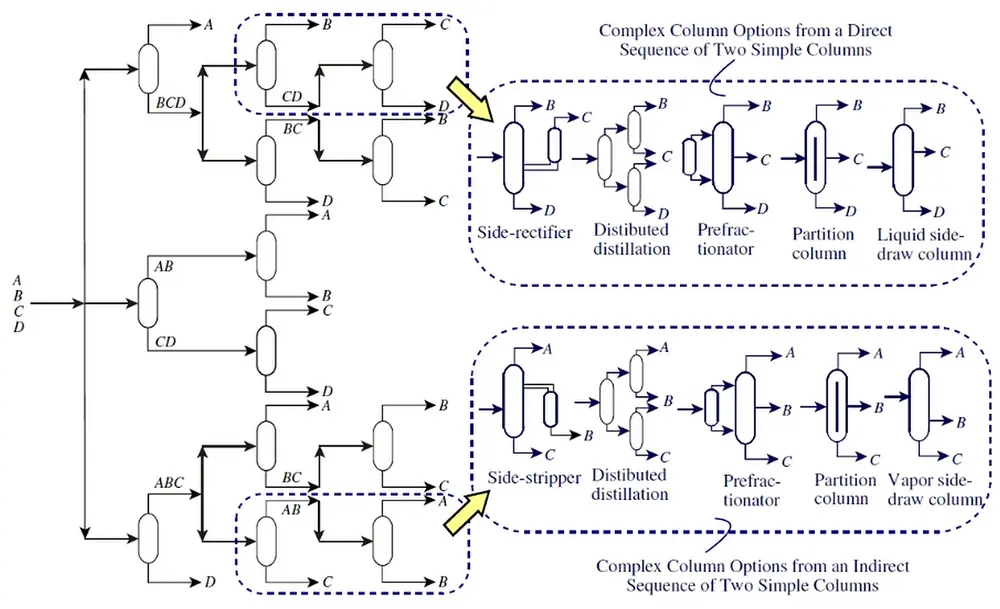

One way this can be achieved is through the optimization of a superstructure. Figure 2 illustrates the approach for a distillation arrangement to separate four components. A grand design (superstructure) is created that involves all possible sequences using simple and complex columns. In principle, any two columns in the superstructure can be merged together to give different complex column arrangements. [3]

Whilst this structural optimization can account for different configurations of the separation system, the optimization must include energy costs. Thus, the optimization must allow change in the column pressure, reflux ratio, feed condition, change from total condenser to partial condenser and change from partial condenser to total condenser. To determine the costs of energy for a configuration, all possible combinations of connection between heat sources and heat sinks must be optimized. The connection between heat source and heat sink might be direct through heat exchangers, or indirect (via a heat pump). Thus the optimization needs to account for the cost of direct heat exchange (including utilities) or the cost of a heat pump if the heat sink is at a higher temperature than the heat source. All of this can be accommodated in a simultaneous, albeit complex, optimization.

challenges and opportunities

Major changes are needed in the way the process industry uses energy in the future. In the past when power was generated by burning fossil fuels in centralized power stations, the resulting economics would dictate that power would be somewhere between 3 to 5 times more expensive than heat. However, as sources of energy change from fossil to renewable it is likely that the price differentials between power and heat will change significantly. Power and heat could become comparable in value, and even possibly power becoming cheaper than heat. Given that distillation is basically a heat driven process, this will have a significant impact on the source of heat. It seems unlikely that the source of heat in distillation will be taken directly from electricity with electric heaters. Rather, the heat currently supplied by steam generated from fossil fuels could be replaced by steam generated by electric heating. This will have major changes in terms of the design of the steam systems servicing distillation. Another feature of cheap electricity will be that heat pumping will become economically far more attractive and more widespread in its application.

References

[1] Kiss, A. A.; Process intensification: Industrial applications, in Segovia-Hernandez, J. G.; Bonilla-Petriciolet A. (Eds); Process intensification in chemical engineering: Design, optimization and control, Springer International Publishing, 2016;

[2] Kiss A. A., Smith R., Rethinking energy use in distillation processes for a more sustainable chemical industry, Energy, 203, 117788, 2020;

[3] Smith R., Chemical Process Design and Integration, John Wiley & Sons, Chichester, UK, 2016.

About the author

Anton A. Kiss is full professor at:

• The University of Manchester, School of Chemical Engineering and Analytical Science, Centre for Process Integration,

• Delft University of Technology, Faculty of Applied Sciences (TNW), Biotechnology & Chemical Engineering Dept.

TonyKiss@gmail.com