Process systems engineering (PSE) … to infinity and beyond!

PSE has been shifting frontiers over the last decades, finding and defining its role for the (petro)chemical industry, the pharmaceutical industry, the food-water-energy nexus, etc. In this contribution, I will shortly sketch the road that PSE in the Netherlands has traveled over the last 15 years and my current PSE related activities at the University of Twente.

A BRIEF history

In the 2000s, PSE professors were reoriented or retired without any succession. The remaining staff gradually moved into industry or departed from the Netherlands on adventures abroad. I moved to Bremen and established a chair on PSE in the energy transition. Tony Kiss moved to the UK, and Richard Lakerveld moved to Hong Kong. With this exodus came a positive movement too. In 2016, PSE-NL was founded as a network for PSE professionals. Ever since, the network has been organizing workshops and symposia, and it can count on a devoted and active community. New Dutch delegates for the EFCE working party on CAPE (Computer-Aided Process Engineering) were installed (namely Tony Kiss, Cristhian Almeida, and myself). We were working abroad but our hearts were in the Netherlands. In our capacity of CAPE delegates, we hosted a very successful ESCAPE (European Symposium on Computer-Aided Process Engineering) in the Netherlands in 2019. The conference was busily attended, and I do believe it brought Dutch PSE back on the international radar. Activities were organized, people got to talking, and it was said that, at a NPS Captain’s dinner, a strategy was devised to re-establish PSE research and education at the Dutch universities by means of the 'top sector funds'. In 2020, new professorships and tenure-track positions were filled, and PSE began its revival.

PSE lab @ Twente

PSE at the University of Twente looks into the challenges prompted by the energy transition: uncertainty, multi-criterion decision-making, and combinatorial complexity in models for process design and operation. Biomass, hydrogen and carbon dioxide are in focus. Models can be used to describe process systems at different levels: from individual unit (e.g. electrolysis cell), to plant (e.g. methanol or ammonia production facility), up to complete supply chain. It is clear that information is exchanged between these levels of the process system. Decisions made in the design of a supply chain have consequences for the factories in said supply chain. The design of said factories in turn influences the choices made for their equipment.

It's not easy to connect different models at different levels

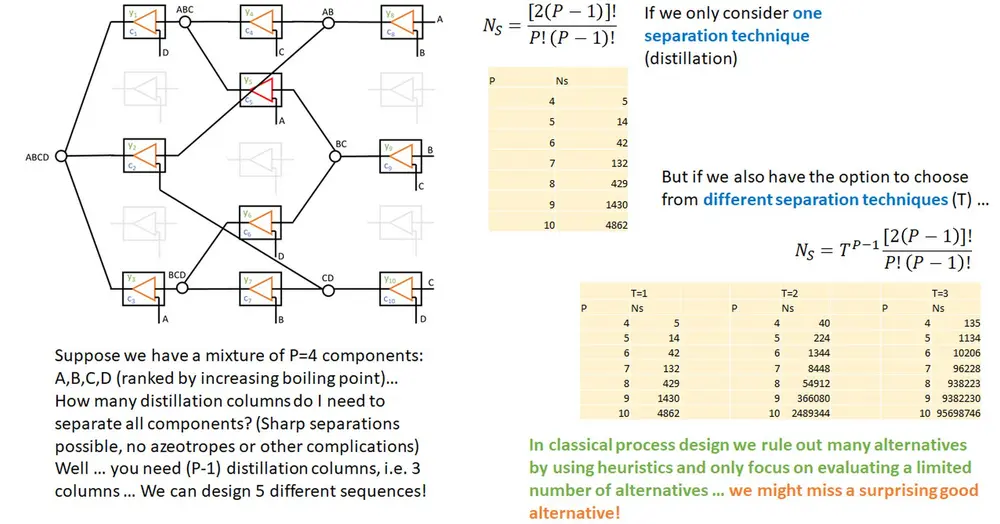

It's not easy to connect different models at different levels: models are described with different mathematics formalisms and software. Units are modeled with differential equations (dynamic balances), plants are modeled with algebraic equations (steady state balances), while supply chains are described with higher level equations that contain continuous and discrete variables. In some cases, models are just not at hand and decisions are made with heuristics. The different modeling languages make integration cumbersome and inconsistent, so that the model in turn has to be decomposed to obtain tractable solutions. I call this the integration paradox. The paradox can be broken through standardization of models. I established the superstructure pit stop team for standardization. Superstructures are maps that take you from raw material to product via different processing steps, showing all possible routes. The formulation of models and optimization algorithms enables us to identify the most promising ones, depending on the goal (economy, environment, risk, etc.).

Concept of a superstructure and how technology and components increase the number of potential processing pathways

In 1980, Formula 1 pit stops took nearly two whole minutes before the cars could resume the race. In 2022, they take mere seconds. This huge difference is the result of learning experience and standardization. This is exactly what I have in mind for our superstructure pit stop. We are testing it on the design of processes for the production of added value chemicals from algae or for the production of green ammonia via renewable hydrogen.

DESTINY

PSE has an important task in the fight against climate change. The process industry takes a central role in providing wealthier and healthier people with new consumer goods, energy, water, medicine, etc. In this central position, however, it creates environmental burdens. There is urgency to turn the tide, and this requires a serious transformation. The Dutch industry can take a world-leading position in this transformation. We are setting up a research program for this transformation: namely the DESTINY program (a DEcision-Support architecture for Tomorrow’s process INdustrY), with three areas of transformation:

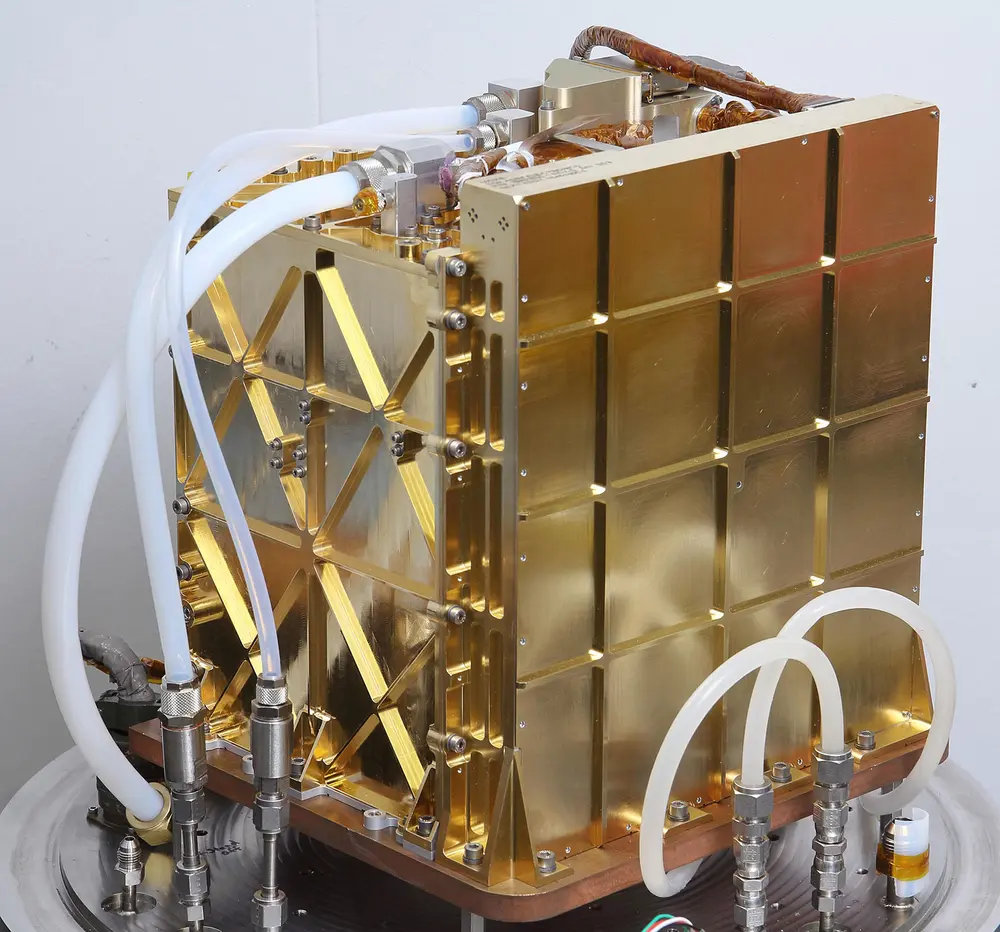

- The process smart grid: towards the model-based design of small-scale, safe, mobile, and resilient production systems that are connected to the civil/urban community.

- A supply-driven process industry: new feedstocks & drastic energy reductions using data analytics and artificial intelligence.

- A new process/project design paradigm: the need for drastically shortening the time to market for new/retrofit processes and products by evolutionary methods.

Researchers and industry have to develop new technology and train a work force for the envisioned metamorphosis. Such a dream might become reality if structural positioning and support takes off in the coming years … to infinity and beyond!