Sound decision-making by Process Systems Engineering

Using the power of models to push the frontiers of innovation in sustainable process technology

The performance of a chemical process depends on the interaction of its parts, not on the parts taken separately, as a system is not the sum of its parts but a product of their interactions. Process Systems Engineering (PSE) is about making educated sound decisions at all levels and size / time scales, by understanding complex systems and the interactions of their parts and finding the best solutions to any problem. This article provides some of the PSE directions that are or will be explored at TU Delft.

Process Systems Engineering

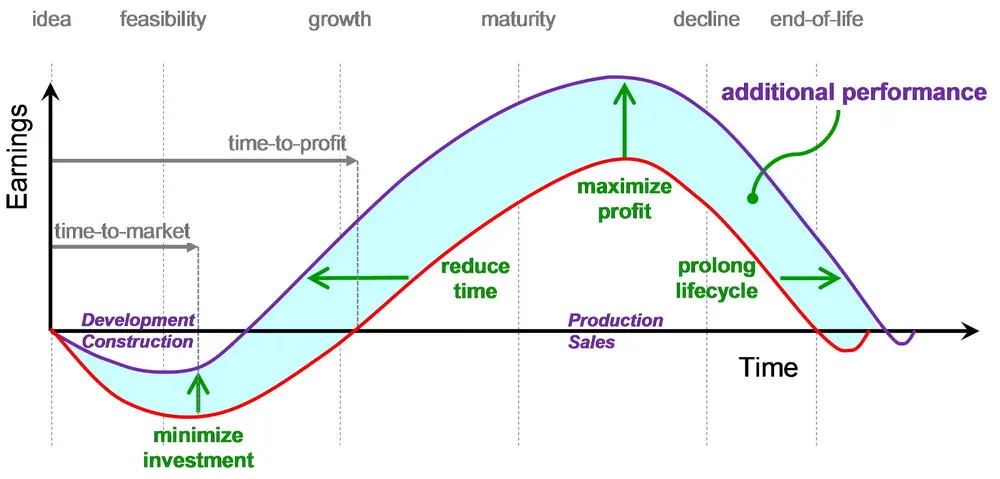

PSE has been an active research field for about 50 years, and its key achievements include methods and tools to support process modelling, simulation and optimization. Model-based applications are central to all PSE domains, including product & process design, optimization, control and operations. Yet, systems thinking and systems problem-solving must be prioritized by PSE, rather than the mere application of computational problem-solving methods. PSE also plays a key role in new research development and the education of the next generations of chemical engineers. In industrial settings, PSE has a vital role in delivering better performance (e.g. profit, sustainability metrics) in shorter time, along all phases: R&D, engineering, process control and optimization, operation, etc. (see Figure 1).1

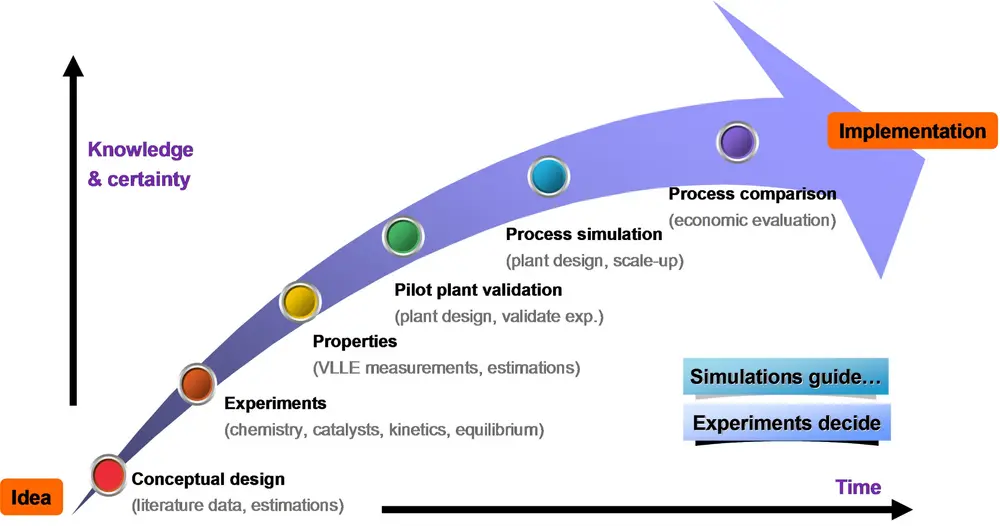

Since models are central knowledge carriers in PSE, their experimental validation is crucial. Figure 2 illustrates that PSE offers a structured approach in both process and product development by guiding lab-scale experiments, interpreting the experimental observations, and translating the results into the desired outcome.2

Figure 2: PSE supports all research & development steps to go from an idea to process implementation

Process intensification & integration

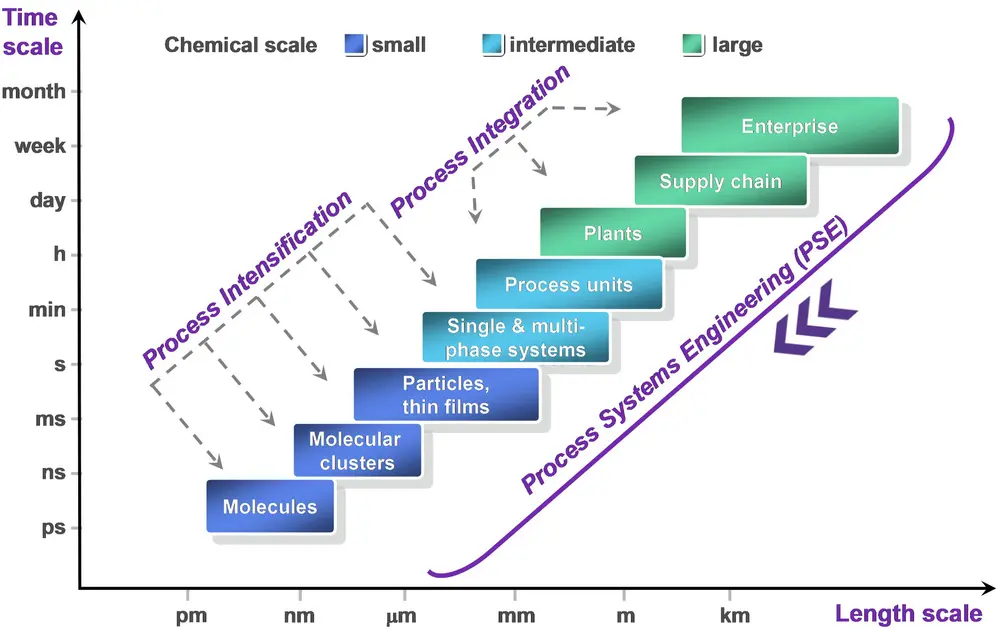

PI&I is all about doing more with less (better, cleaner, safer, cheaper), in a smarter and integrated approach, being complementary to PSE at various scales (as shown in Figure 3).3 Designing and retrofitting a chemical process with PI options requires integration of unit operations, functions, and phenomena, as well as targeted enhancement of rate of a phenomenon.1,4

PSE & PI professionals are connected by a joint goal (substantial improvements in process performance), but they master different skills and they differ in the scientific approach and methods in a complementary way. At TU Delft, we aim to grow the PSE field and skillfully integrate PSE with PI&I expertise in order to solve major industrial problems in the transforming context related to a circular economy.

Figure 3: Process intensification and integration are complementary to PSE at various scales

Circular production systems

The development and design of circular production systems gets a central role in the society and in industry. Bio-based processing systems3 fit well in this category and they will benefit from the synergy of two departments: ChemE and Biotechnology. Circular economy (CE) aims to solve resource, waste, and emission challenges by creating a production-to-consumption total supply chain that is restorative, regenerative, and environmentally benign. It does this by keeping products, components, and materials at their highest utility and value, with minimal to non-existent waste at all times. PSE plays a central role to help CE, which can be viewed as an operational tool with specific goals, aimed for businesses to achieve sustainability. In this respect, at TU Delft we aim to develop new computational tools and methods that support the needs of circular design and green processes (e.g. bio-refineries producing bio-based fuels and chemicals).

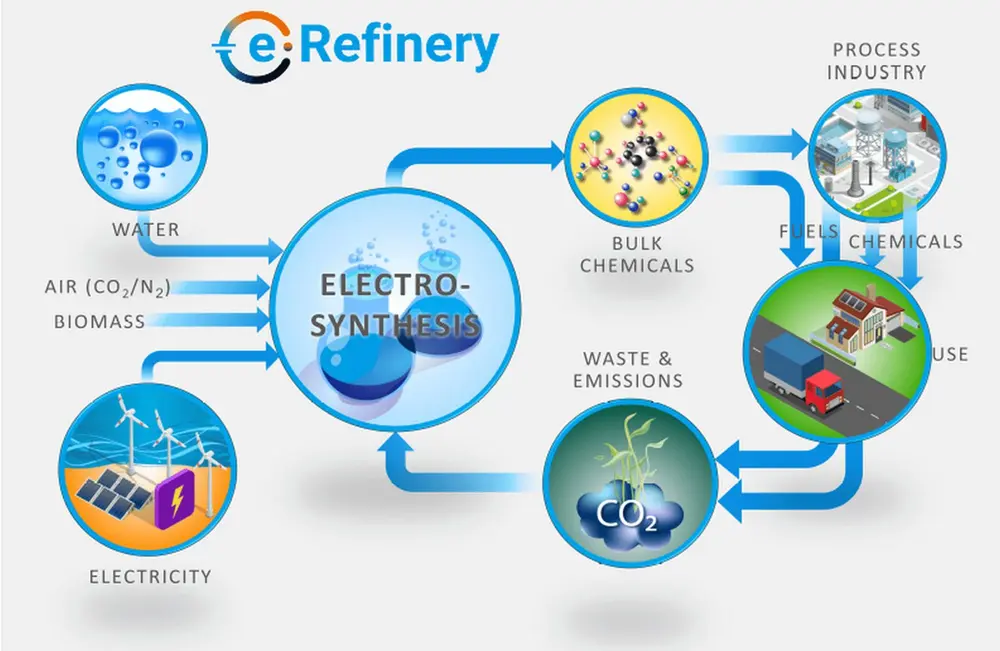

Electrochemical operations

The energy transition has far-stretching implications for chemical companies and in the future, a process plant without an electrochemical conversion step will probably be a rarity.5 From a process integration perspective, power will be another shared resource in a process to be optimally used. The e-Refinery project at TU Delft (Figure 4) enables industry partners to start building the required technologies for electrochemical conversion of green electricity into fuels and chemicals, from molecular scale to large-scale system integration. e-Refinery tackles key challenges that the society is facing: CO2 neutral fuels, seasonal energy storage, and a defossilized chemical industry. PSE aids here by developing novel models and approaches for integrating the process design and dynamic operational policies in an optimum way.

Concluding remarks

PSE can and will address the main challenges and opportunities that arise due to the move from a linear to a circular supply chain in all industrial sectors. Tools and methods from PSE for CE will include among others multi-scale modeling, life cycle assessment, and process intensification.6,7 Using a PSE approach can have a large impact on the understanding, analysis, and optimization of CE supply chains, and the convergence of different disciplines towards a common vision. At TU Delft there are several clusters of projects (e.g. energy, food & pharma, water processing and advanced materials) within the Process & Product Technology Institute (Pro2Tech) that will profit from a strong PSE contribution at all scales. Besides research, the education of (bio-)chemical engineers in the PSE domain will significantly benefit from the new developments, adapting to match the new industrial needs of the modern society.

Anton A. Kiss

Delft University of Technology, Faculty of Applied Sciences (TNW), Biotechnology & Chemical Engineering Dept., Van der Maasweg 9, 2629 HZ, Delft. TonyKiss@gmail.com

REFERENCES

1. Kiss A. A., Grievink J., Process Systems Engineering Developments in Europe from an Industrial and Academic Perspective, Computers & Chemical Engineering, 138, 106823, 2020.

2. Kiss A. A., Process Intensification: Industrial Applications, in Segovia-Hernandez J. G. and Bonilla-Petriciolet A. (Eds.); Process Intensification in Chemical Engineering: Design, Optimization and Control, Springer International Publishing, 2016.

3. Kiss A. A., Grievink J., Rito-Palomares M., A Systems Engineering Perspective on Process Integration in Industrial Biotechnology, Journal of Chemical Technology and Biotechnology, 90, 349–355, 2015.

4. Kiss A. A., Novel Catalytic Reactive Distillation Processes for a Sustainable Chemical Industry, Topics in Catalysis, 62, 1132–1148, 2019.

5. Kiss A. A., Smith R., Rethinking Energy Use in Distillation Processes for a More Sustainable Chemical Industry, Energy, 203, 117788, 2020.

6. Avraamidou S., Baratsas S. G., Tian Y., Pistikopoulos E. N., Circular Economy – A Challenge and an Opportunity for Process Systems Engineering, Computers & Chemical Engineering, 133, 106629, 2020.

7. Tian Y., Demirel S. E., Hasan M. M. F., Pistikopoulos E. N., An Overview of Process Systems Engineering Approaches for Process Intensification: State of the Art, Chemical Engineering and Processing – Process Intensification, 133, 160–210, 2018.