A solar-powered chemical mini-plant

An off-grid and autonomous system for fine chemical production

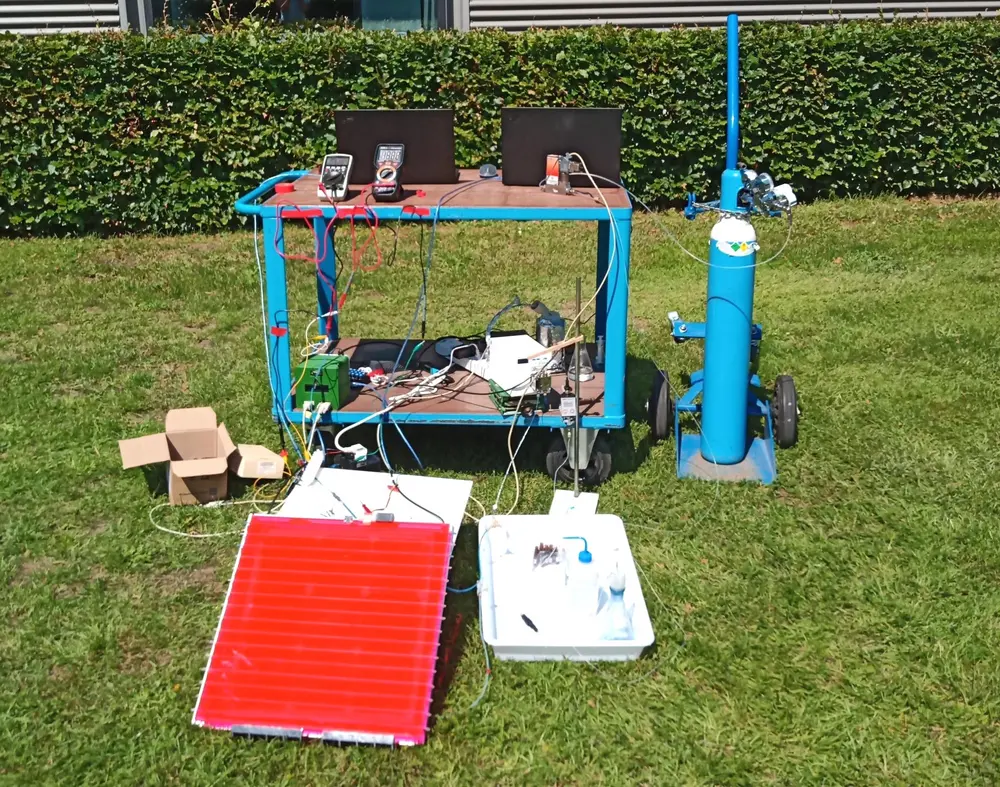

Solar photochemistry is an eco-friendly alternative for the production of fine chemicals outside the traditional laboratory or chemical plant environment. However, variations in solar irradiation conditions and the need for additional energy sources to power ancillary equipment can limit its applicability and feasibility. To address these drawbacks, we recently introduced an autonomous solar-driven chemical “mini-plant” centered around a scaled-up luminescent solar concentrator photomicroreactor (LSC-PM).

Flow photochemistry

The increasing worldwide energy demand and environmental issues generated by fossil fuels consumption are pushing the world towards new and renewable technologies. In this context, the chemical industry is heading towards flow chemistry to diminish the power and volume of solvent consumed by existing production plants. In particular the field of continuous micro/milli flow synthesis coupled with photochemistry is promising for this transition by allowing shorter reaction times and milder conditions, thanks to enhanced mass and heat transfer, whereas the shorter path length required for light to travel greatly improves the homogeneity and efficiency of reaction mixture irradiation. In practice, this irradiation is often provided by the use of LEDs or medium pressure lamps, but to further reduce the impact on the environment we opted to utilize solar irradiation.

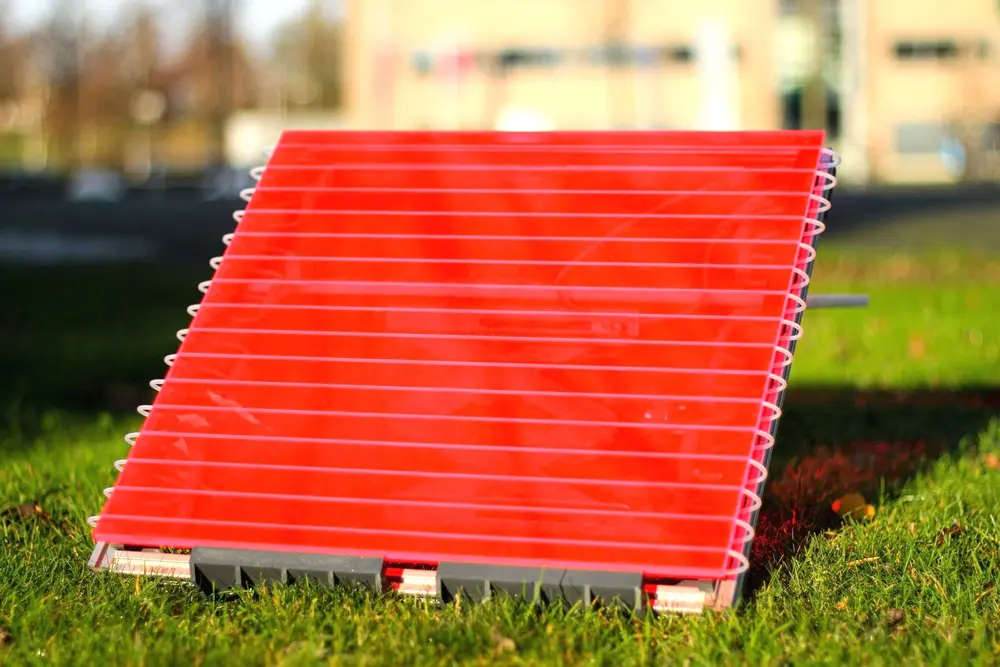

The LSC-PM

In order to efficiently use sunlight, it must first be collected and concentrated towards the reaction mixture. To achieve this, we combined reactor design with luminescent solar concentrators (LSC). LSCs consist of a waveguide material doped with organic dyes that absorb and re-emit light, and subsequently entraps photons via total internal reflection, effectively concentrating light towards the edges of the material. We previously introduced a small-scale LSC photomicroreactor (LSC-PM), where the reaction channels are inserted into this material. Not only does this insertion intercept the concentrated light, but matching the emission of the luminescent dye and the absorption band of the photocatalyst makes better use of the solar spectrum. Furthermore, LSCs can harvest both direct and diffuse light, removing the need of a solar tracking system and ensuring continuous operation even under variable weather conditions. The promising results that were obtained with previous small-scale prototype reactors fueled our desire to scale up this concept to a “mini-plant”, that would be self-sufficient and reliable in operation.

When solar chemistry is the center of a design, limitations are created bound to the geographical position of the process

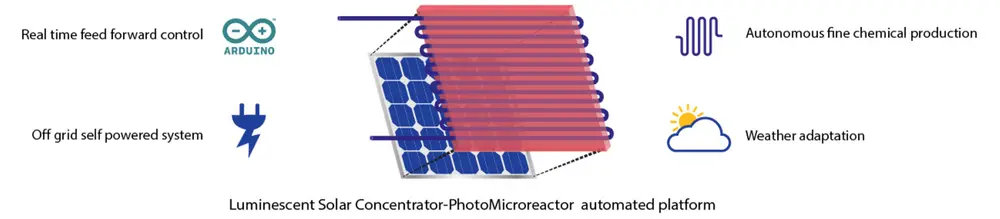

Autonomous operation

Despite the ability of the LSC-PM design to utilize both direct and diffuse irradiation, the variations in light intensity and passing clouds need to be taken into account for continuous operation. To this end, a responsive control system was designed that rapidly adapts the flow rate of the reagents dependent on the photon flux received by the reaction channels. When the cloud coverage increases and the light intensity drops, the pumps will slow down to increase the residence time of the chemicals in the reactor to provide a sufficient irradiation time for the desired product yield. This approach is essential to have a stable quality at the outlet of the photochemical reactor.

Since the LSC-PM does not absorb the full range of the solar spectrum, a fraction of this irradiation will be transmitted through the bottom surface of the reactor. To make use of this energy, a solar panel was implemented on the back of the reactor. In this way, photons unable to generate a chemical transformation can be used to produce electricity to power the ancillary equipment of the mini-plant. This allowed the setup to be self-sufficient and fully operational off-grid for our demonstration in Eindhoven, The Netherlands.

Worldwide potential

When solar chemistry is the center of a design, limitations are created bound to the geographical position of the process. It is more intuitive to use solar photochemistry in the south of Spain for example than in northern locations like Norway. However, the implementation of this mini-plant is possible in remote locations thanks to the versatility of the system. To support this claim of general applicability, we simulated the behavior of our LSC-PM based on representative spectral data and ray tracing simulations. These simulations helped determine the optimal reactor tilting orientation without the need for solar tracking and estimate the relative productivities that could be reached with this system for several different locations on earth.

Conclusion

We developed a solar-powered, autonomous chemical mini-plant for producing fine chemicals under fluctuating solar light irradiation, which consists of a scaled-up LSC-PM, that converts and guides light towards embedded reaction channels to drive photochemical transformations. A control system assures almost instantaneous adjustments in the chemical feed even in rapid weather-changing environments. Photovoltaic cells were integrated underneath the reactor to power the system in an energy-neutral manner. By testing, validating, and simulating the solar mini-plant, we demonstrated its potential for the green production of chemicals.

Timothy Noël, Stefan Zondag and Tom Masson (Flow Chemistry Group, van ’t Hoff Institute for Molecular Sciences (HIMS), University of Amsterdam)

Further reading:

(1) Masson, T. M.; Zondag, S. D. A.: Kuijpers, K. P. L.; Cambié, D.; G. Debije, M. and Noël, T. Development of an off-grid solar-powered autonomous chemical mini-plant for producing fine chemicals. ChemSusChem 2021, 14 (24), 5417-5423

(2) For a review on the topic: Zondag, S. D. A. ; Masson, T. M.; Debije, M. G. and Noël, T. The development of luminescent solar concentrator-based photomicroreactors: a cheap reactor enabling efficient solar-powered photochemistry. Photochem Photobiol Sci 2022 DOI: 10.1007/s43630-021-00130-x