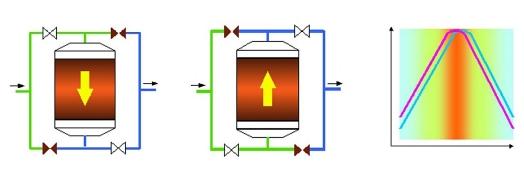

REVERSE-FLOW REACTOR

A reverse-flow reactor is a fixed-bed adiabatic reactor in which the locations of inlet and the outlet are periodically switched (see figure 1). This way the middle part of the reactor can operate at a very high temperature (typically 500 °C), while the outlet temperature is only the inlet temperature plus the adiabatic temperature rise (typically 40 °C). Hence, a reverse-flow reactor operates in the temporal regime and combines the functions of heat exchange and reaction in a single vessel. The periodic operation causes an effective counter-current heat exchange, without the need to install heat exchangers at the front and the back of the reactor. This way investment cost is strongly reduced compared to a conventional set-up of a reactor with a heat exchanger to recover the heat from the outlet and use it to heat the feed stream. The first implementation was in 1982 [1]. By 2012 thousands of these reverse flow reactors were in commercial scale operation [3]. Reverse flow reactors are used in dilute gas systems with a limited adiabatic temperature rise [2]. They are used in SO2 oxidation, NOx reduction, N2O decomposition and VOC oxidation [1]. Either a heterogeneous catalyst is employed or inert ceramic materials. For VOC oxidation Bunimovich shows the cost advantages when using a catalytic system [4]. For a VOC oxidation of a gaseous effluent of an ethylene oxide plant Mc Namara describes a system with ceramic balls [5].

Technology providers

Technology providers are Matros Technologies, Holder Topsoe, Babcock Power Inc., Sumiko Eco-Engineering, MEGTEC and CANMET [1]. The driving forces for these applications are environmental legislation to remove contaminants in effluent gases to the atmosphere and reduced investment cost compared to conventional solutions with a heat exchanger [2]. The investment cost is typically reduced by a factor of 4 and in some cases energy is also saved [2]. Design and modelling knowledge of this technology is of course key for implementation on a commercial scale. This knowledge is available at Matros Technologies [6]. A very good description of the design principles for reverse-flow reactors is provided by Eigenberger [7]. Marin provides a simplified 'pseudo steady state' design solution specifically for hydrocarbon combustion [8]. Scale-up has been carried out by modelling and validation by pilot plant tests [2, 9].

By Jan Harmsen (Harmsen Consultancy BV)

References

[1] G.A. Bunimovich and Y.S. Matros, Presentation, Chemreactor-19 conf., Vienna, 2010

[2] Y.S. Matros, G.A. Bunimovich, A.S. Noskov, Catalysis Today, 17 (1993) 261-274.

[3] P.L. Silvester and R.R. Hudgins, Periodic Operation of chemical reactors, Butterworth-Heinemann, Oxford, 2012.

[4] G.A. Bunimovich and Y.S. Matros, Saving Energy in Regenerative Oxidizers, Chemical Engineering, March (2010) 26-32.

[5] D. Mc Namara, et al. Mission impossible, Hydrocarbon Engineering March (2006) 1-4.

[6] www.matrostech.com

[7] Gerhart Eigenberger∗, Grigorios Kolios1, Ulrich Nieken, Thermal pattern formation and process intensification in chemical reaction engineering, Chem. Eng. Sci. 62 (2007) 4825-4841.

[8] M.P. Marin, et al., Simplified design methods of reverse flow catalytic combustors for the treatment of lean hydrocarbon-air mixtures, Chemical Engineering and Processing: Process Intensification, 48 (2009) 229-238.

[9] C. Isozaki, T. Katagiri, Y. Nakamura et al. in: "Unsteady State Processes in Catalysis, Proc. of the Int. Conf. (5-8 June, 1990)", Novosibirsk, USSR, VSP, Utrecht-Tokyo, 1990, p.637.